Charlie has been with ATS for nearly two decades. He wears many hats at ATS as the safety instructor for flatbed cargo securement. He takes drivers through flatbed securement training in orientation and is the point person for drivers who have questions on the road. He’s also able to answer any hazmat questions drivers may have.

- What CVSA Brake Safety Week is (and why it matters)

- 2025 Brake Safety Week dates and focuses

- Compliance tips for drivers

The 2025 Commercial Vehicle Safety Alliance’s (CVSA) Brake Safety Week is coming up fast at the end of August. Knowing what’s happening, when, and why is critical to your preparation — and to ensuring you stay moving without issue during this time.

That’s right: if you’re pulled over for a brake system inspection during Brake Safety Week and a violation is found, you could be sidelined for your own safety and that of the motoring public.

No matter what role you play in the trucking industry — driver, carrier, or shipper — delays of any kind can have a serious impact on your timeline and bottom line.

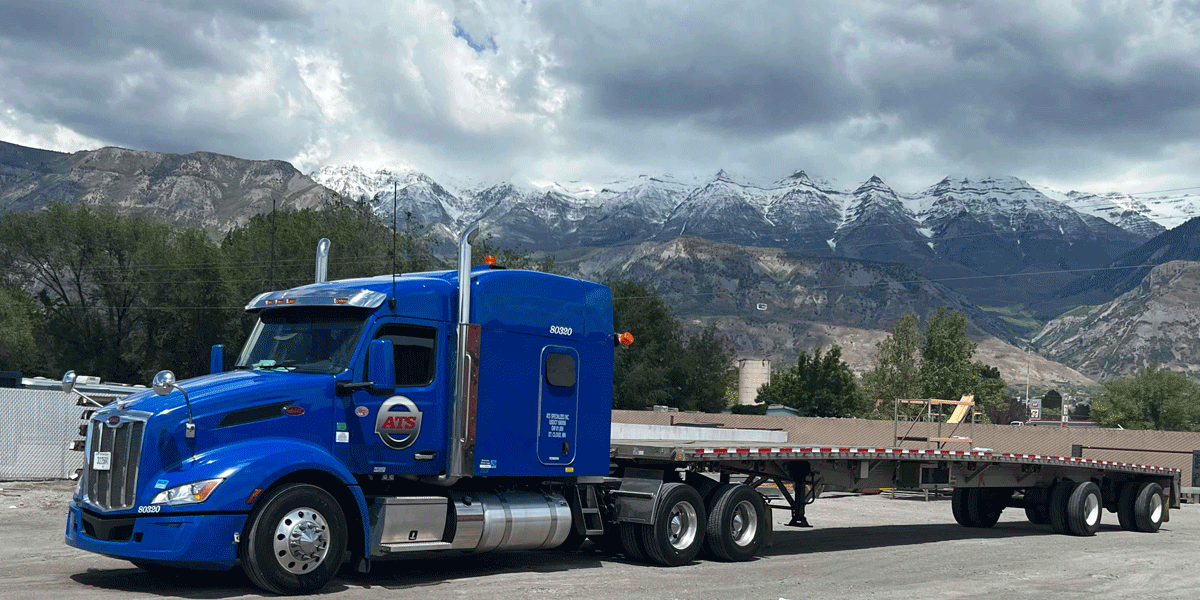

Anderson Trucking Service (ATS) is here to help you avoid these movement restrictions by passing your brake safety inspections with flying colors.

We see our own drivers go through these tests each year, and we’re ready to walk you through what to expect, so you can approach an inspection with ease and confidence.

Let’s get started!

What CVSA Brake Safety Week Is (and Why It Matters)

CVSA Brake Safety Week was introduced as part of Operation Airbrake, a joint program between the CVSA and the FMCSA that launched in 1998.

Operation Airbrake is dedicated to improving CMV brake safety throughout North America. Brake Safety Week is one of two annual brake safety campaigns held by the program.

During Brake Safety Week, CVSA-certified inspectors conduct routine CMV inspections focused on brake systems and components. The inspections also include a special focus area that changes annually.

The CVSA reports that during the 2024 Brake Safety Week, nearly 13 percent of the 16,725 CMVs (some 2,175 trucks and buses) inspected had brake-related violations. These violations resulted in immediate restriction from travel until the issues were corrected.

The urgency of these violations is no overreaction. According to the Federal Motor Carrier Safety Administration (FMCSA), brake systems are one of the most cited vehicle-related factors in fatal crashes between commercial motor vehicles (CMV) and passenger vehicles.

Improperly installed or poorly maintained brake systems can affect a driver’s braking ability and reduce their stopping distance, which poses a serious risk to both the driver and the public.

A truck driver’s role in maintaining properly installed brake systems is therefore critical to upholding safety for all who travel North American roadways.

2025 CVSA Brake Safety Week Dates and Focus

This year’s CVSA Brake Safety Week will take place from Aug. 24-30, 2025.

Trucks traveling in North America during this time may be subject to routine vehicle inspections by CVSA-certified inspectors. The CVSA posts the full procedure for its Operation Air Brake inspections on its website to help drivers know what to expect.

The special focus area for the 2025 CVSA Brake Safety Week will be the condition of the brake drum and rotor.

According to the CVSA, brake drum and rotor issues can affect a vehicle’s brake efficiency. If a broken piece of a drum or rotor became dislodged from the vehicle as it traveled, it could cause severe damage to other vehicles or result in injuries or death to the motoring public.

Per the CVSA, if you’re inspecting your vehicle’s brake drum and rotor on your own, be on the lookout for:

- Cracks or broken pieces in the friction surface of the rotor

- Cracks or missing pieces in the outer portion of the drum

- Rust on the rotors

These problems are visible to the naked eye and are red flags that indicate potential for loose pieces (which could become dangerous to other vehicles and drivers on the road) and/or inoperative brakes.

The CVSA has compiled an informative flyer featuring eight brake drum and rotor tips to help drivers prepare for inspections during Brake Safety Week, and to help them perform thorough inspections of their own all year round. The flyer is available to download for free in English, Spanish, and French at CVSA.org.

If inspectors find that you’re not compliant, you can be placed out-of-service until the issue is fixed. That not only can result in compliance, safety and accountability (CSA) points, but it can also have a huge impact on your wallet and your time.

You’ll need to sit on the side of the road in on-duty standing until a road service crew can fix your truck. That can take hours, and you’ll pay a steep charge. You’ll not only have to pay a standard repair fee, but you’ll also pay a mileage fee and an hourly rate. Conversely, your truck may need to be towed to a shop. Neither of these are a cheap solution.

That means its best for you to do what you can to ensure your truck is in tip-top shape heading into Brake Safety Week (and all year round, of course).

Brake Safety Week Inspection Compliance Tips for Drivers

Our first tip for helping you stay in compliance this CVSA Brake Safety Week is to take advantage of all the resources available to you from the CVSA and FMCSA as you prepare.

We’re linked many resources provided by these agencies throughout this article, and their information is straight from the source. The folks who trained your Brake Safety Week inspector also wrote these guides — so think of it like an open-book test and study up.

Aside from reading up on the inspection procedures and this year’s area of focus, here are some additional tips to help keep you moving this Brake Safety Week.

Inspect Your Brakes

Bet you saw this one coming! The first step toward compliance is to inspect your brake system and components before each trip to ensure they're in good working order.

During your pre-trip inspections:

- Look at the brake pads and lining to ensure that they’re the proper thickness and there aren’t any large cracks.

- Make sure they aren’t covered in oil or grease.

- Make sure there's adequate lining and nothing is missing or cracked.

You should also perform your three-step air brake test during your pre-trip. Before performing the test:

- Build air pressure until you hear the relief valve pop

- Put the truck in first gear

- Shut off the motor

- Push in both valves to release brakes

- Turn the key back to the on position, but don’t start the truck

Once this process is completed, you can complete the three-step air brake test:

Step 1: Hold firm pressure on the brake pedal for 60 seconds. Watch the air gauges and look for no more than a four-pound per square inch (PSI) drop.

Step 2: Pump the brakes until you see/hear the low air warning indicator. It should be at 60 PSI.

Step 3: Continue pumping until you see both brake valves pop. It should be between 20-30 PSI.

To ensure your brakes are always in adjustment, complete 10 full brake applications while parked. You can do this while you’re waiting in line during the inspection process as well. It’ll ensure that the automatic slack adjusters have adjusted the brakes to compliance.

You have brakes on the tractor itself and the trailer; both sets should be working together properly. Likewise, the brakes on the left side should be working in conjunction with the brakes on your right side.

If you sense that something isn’t functioning properly with your brake system, take your truck in.

Without a balanced brake system, you may notice your vehicle pulling to one side as you brake. This can lead to loss of control.

Even just one or two brake chambers not working properly will result in a reduction of function. It’s best to get it in as soon as possible so that you have time to get the issue fixed before Brake Safety Week is upon us.

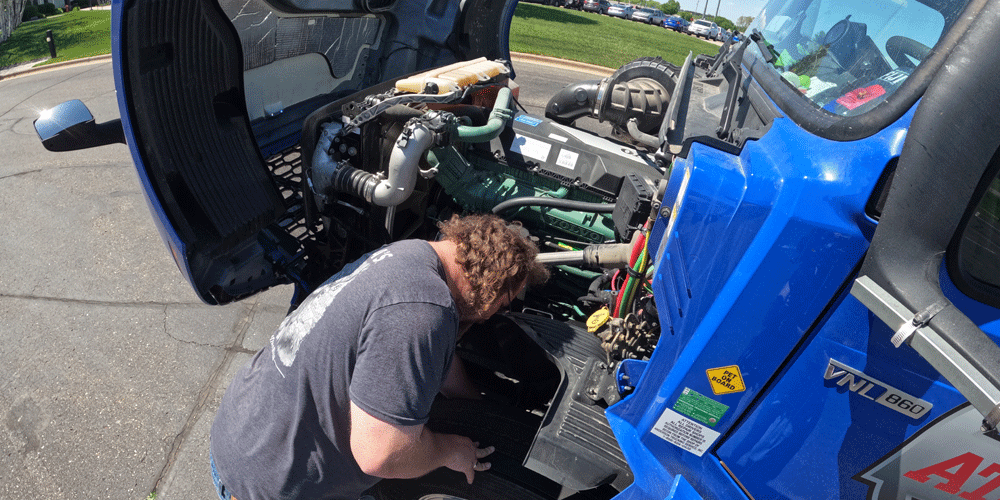

Go In for Regular Brake Maintenance

Go In for Regular Brake Maintenance

Many brake issues can be solved quickly and easily by taking your truck and trailer in for regular maintenance. Brake maintenance should be performed regularly, ideally every time you go in for an oil change.

Here are some things to keep in mind during brake maintenance:

- Brake parts should be replaced as needed.

- If your brake pads are worn and need to be replaced, you’ll need springs, pins and bushings.

- If you need to replace the brake drums, you’ll need to replace the shoes as well.

- Your slack adjusters should be greased so they don’t seize up and lead to brake failure.

- Your air compressor pressure gauge should be checked to ensure it reads above 60 PSI when the vehicle is off and between 100-125 PSI when it’s running.

- Your hoses and linings should be in good condition, with no cracks or signs of leaks. They should all be at least one-fourth of an inch thick.

Without getting under your vehicle, monitoring brake performance is challenging. You can’t simply check your brakes like you can check your lights or tires. You can do a visual inspection of your brakes, but it’s best to go in for regular brake maintenance performed by professionals.

Follow Proper Braking Techniques

Remember your training and follow proper braking techniques to prevent excessive wear and tear on your brake system. Be mindful of your following distance and speed as well.

Loading too much weight with no regard to appropriate weight limits can also strain your brakes and lead to issues down the road.

Inspect Your Truck

There are few things scarier than your truck barreling down the road with no brakes to stop it — for the driver and for fellow motorists. CVSA Brake Safety Week is designed to encourage brake safety and decrease the incidence of preventable accidents.

Of course, your brake system is just one part of the complex equation of truck readiness. There are countless things that can go wrong as you travel to your next destination. Performing a pre-trip inspection is the best way to ensure your truck is road ready. They should never be skipped.

Check out our pre-trip inspection guide to get the rundown on the importance of pre-trip inspections and the parts of your truck you should be checking.

Then, learn some roadside inspection tips from a commercial vehicle inspector. to get even more expert insights into the inspection process.