Jason started with ATS in October 2010 as the prep shop foreman running the unmanned trucks department. He eventually moved into the service shop foreman position and then the trailer shop service leader role. He is currently the shop manager at ATS, a position he has held for just over four years.

The Federal Motor Carrier Safety Association (FMCSA) reported that there were 388,000 accidents in 2018 involving large trucks.

Did you know that a significant number of semi-truck accidents are caused by a total lack of maintenance or poor maintenance?

Yikes.

That means there are a significant number of trucking accidents that are preventable.

Do you find that you often try to push off maintenance as long as you can? If so, you might become a statistic and end up stuck on the side of the road waiting for an expensive tow truck — followed by days of downtime.

At Anderson Trucking Service (ATS), one of the biggest complaints we hear from new drivers is that they have had to spend too much time off the road because of costly breakdowns. They want to ensure that, at ATS, they will receive newer equipment that runs well and is well-maintained by the shop.

By law, carriers are required to maintain their trucks to ensure they are safe enough to be on the roads. It’s your job to ensure you are complicit with this law by keeping up with preventative maintenance.

As the shop manager at ATS, I know a thing or two about how you can avoid breakdowns that will leave you without a truck and losing money.

By the time you finish reading this article, you’ll understand some of the best ways you can prevent costly breakdowns that keep you off the road.

Three ways you can prevent semi-truck breakdowns:

- Schedule preventative maintenance

- Winterize your truck

- Perform daily pre-trip and post-trip inspections

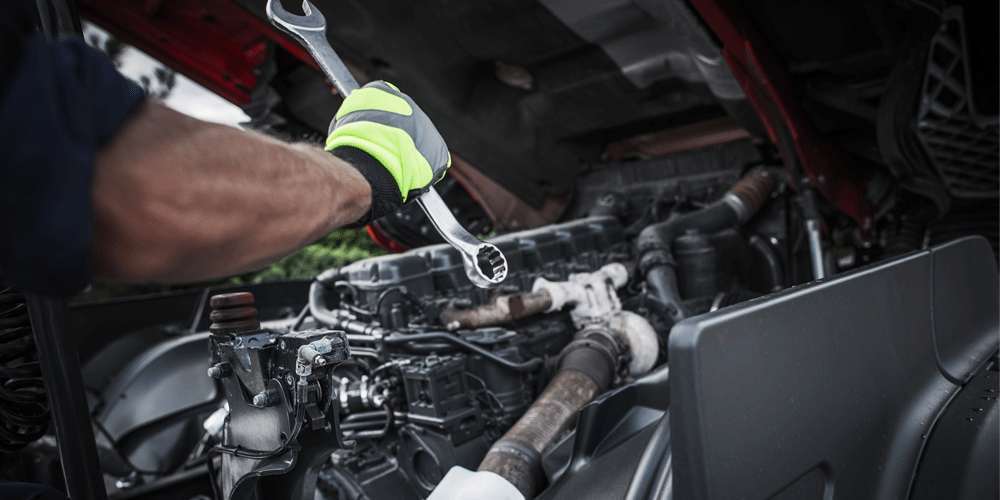

1. Schedule Regular Semi-Truck Preventative Maintenance

Preventative maintenance is one of the best ways you can maximize your income out on the road and prevent downtime.

The top three reasons preventative maintenance is crucial:

- It helps prevent costly breakdowns and saves money

- It can prevent lengthy downtime due to lack of part availability

- It helps you meet your truck warranty requirements

Be honest. How many times have you seen your check engine light come on and you’ve thought to yourself, “I can make another trip or two before I take care of this”?

You wouldn’t be the only driver to have thought this or done this.

There are high costs associated with having maintenance performed on your truck. A company driver will have maintenance costs taken care of, but if you’re an owner-operator or lease driver, you’ll be paying out of pocket to have your truck fixed and maintained. Not only that, but you’ll be losing money while you’re down and waiting for repairs. If the wheels aren’t turning the money isn’t coming in — whether or not you’re a company driver or an independent contractor.

Cost and time may prevent you from taking care of maintenance as you should, but you might change your mind when you realize how much money you can save by avoiding preventable accidents caused by a lack of maintenance.

Some drivers don’t like to have maintenance done because it takes away their road time. However, if you pay close attention to your Hours of Service (HOS), you can plan maintenance during your off hours so that you aren’t wasting any drive time having repairs done.

Performing regular preventative maintenance may be the difference between you breaking down or heading off to pick up and haul that perfect load. If you could prevent costly downtime, why wouldn’t you?

The longer you wait to fix something, the worse it can get — which could lead to more downtime in the long run.

Routine maintenance will ultimately keep your costs down and improve vehicle performance so you can do your job to the best of your ability. You’ll also improve fuel economy and extend the life of your truck. Therefore, it’s in your carrier’s best interests to keep your truck well-maintained, too.

Consider this: Repairing something on the road can cost two to four times more than if you were to have it fixed in the shop. If you see your check engine light go on, schedule shop time immediately. Don’t ignore it.

Performing specific preventative maintenance is also required in order to have repairs covered under a warranty. If you need to repair your truck and it’s still under warranty but you haven’t kept up with proper preventative maintenance, your warranty may not cover the repair because you didn’t do due diligence and take care of the truck. Failing to take care of your truck can make your warranty null and void.

Semi-Truck Preventative Maintenance Checklist

Preventative maintenance doesn’t have to be difficult. It can be as minor as changing the oil and checking fluid levels. When you schedule shop time, your trucking carrier will do some of the following:

- Check fluid levels, including oil, coolant, washer and power steering. Low levels can be a sign of a leak.

- Change fluids when required per manufacturer recommendations.

- Check your tires and look for uneven wear and low tire pressure. Tire blowouts are dangerous, but uneven wear can also be a sign of a bigger problem with your suspension.

- Check your brakes and look for leaking wheel seals.

- Check air filters. A clogged filter can reduce your engine’s power.

- Test the battery and electrical system — especially before the winter.

- Check exterior lighting and signals to make sure they’re working properly.

Your carrier will also look at your cooling and heating systems, the fuel and exhaust system, steering and suspension, mounts, shafts, belts, hoses, mirrors, glass, fifth wheel and seat structure.

Performing regular semi-truck preventative maintenance is a great way to catch potential issues before they become an issue and lead to mechanical failure and potential accidents on the road.

When you notice any issues with your truck while out on the road, keep note of them. Any funny knocking sounds or noises you hear shouldn’t be ignored. Write them down in a notebook or the notes app of your phone. When you visit your shop service advisor, tell them everything that’s been going on with your truck. They want as thorough a picture as possible so they can take care of potential problems before they become disastrous.

By now you’ve probably already heard about the parts shortage. Scheduling ahead of time next time you’re near a shop will ensure the parts are in when you need them. So when you hear that knocking sound, make an appointment.

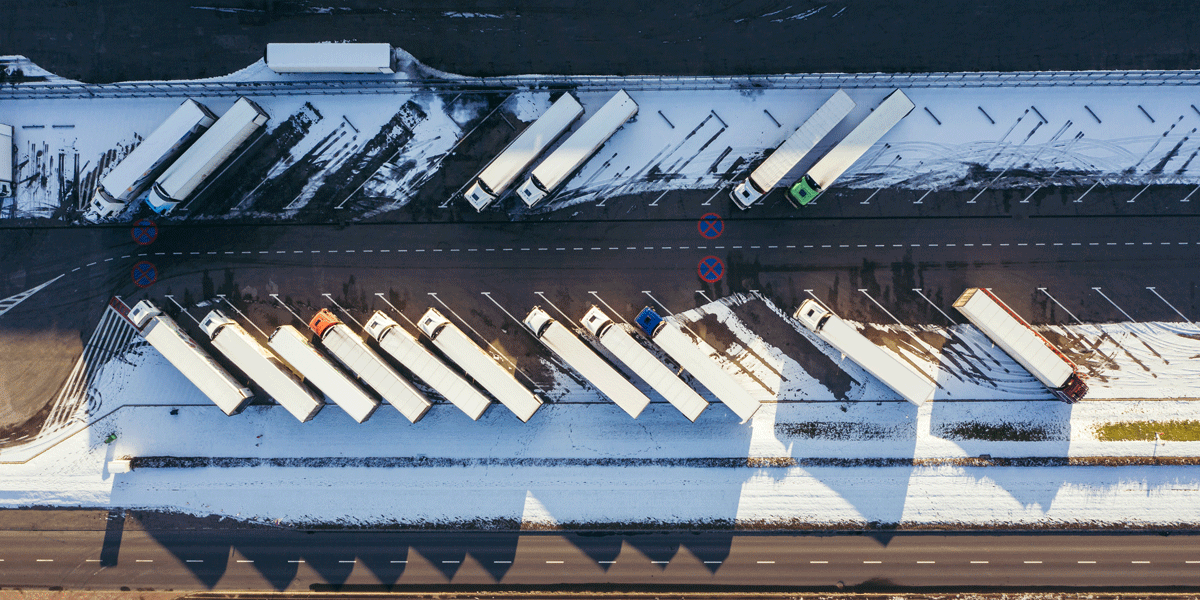

2. Winterize Your Semi-Truck

Truck winterization is an important part of preventative maintenance — especially if you are a driver who frequently drives in the Midwest or Northeast and your truck is exposed to frigid temperatures for a large chunk of the year.

To get your truck ready for the winter and to prevent costly downtime, learn more about how to winterize a semi-truck:

- Switch fuel out to a premium winterized diesel with anti-gelling properties. This fuel is specially formulated to prevent fuel gelling.

- Add anti-gel additives every time you fill up your tank. Keep several bottles in your truck and read the label to determine how to properly concentrate your tank according to the current temperatures.

- Add Diesel 911 to your tank if you have had any gelling in your fuel or a frozen fuel filter. It will restore the flow of your diesel to your engine and you’ll be able to get your truck started again.

- Check your windshield wipers and carry an extra set with you in case yours snap or quit working properly.

- Carry extra fuel filters — they can plug easily in the winter.

- Manually drain the air tanks daily and ensure all the water is out of the tank. Water in the air tank can travel through the brake lines and freeze in the lines on the truck and in the trailer air system.

- Carry tire chains in case the road conditions require it.

- Check your bunk heater to ensure the heat is flowing through the bunk nicely. You may need to clean it out before it gets cold out.

- Check your tire treads. If you have low treads, get a new set for the winter.

In many cases, you can only get access to this special fuel and anti-gelling additives in colder areas, so keeping a surplus in your truck — along with your other winter gear — is best practice. When you’re at shops in the northern part of the country, ask for it.

You could be traveling into the colder areas where you could gel as you’re driving in. You can prepare for this by trip planning and looking at the temperatures of every area you’ll be driving in.

There are a few items you should carry with you during the winter:

- Several sets of warm clothes

- Insulated shoes with good traction

- Winter outerwear

- Candles for heat if your truck breaks down

- Food and water for several days

- Airline antifreeze

- Blankets

- A shovel

- An ice scraper

- Cat litter (to prevent spinning if your truck is stuck on ice)

Along with anti-gel, it doesn’t hurt to also carry extra truck fluids, like antifreeze, brake fluid, power steering fluid and cold weather washer fluid.

You’ll also want to bring a three-pound hammer and a bar in case your brakes freeze. When brake drums heat up, moisture builds up. When you set the brakes in cold weather, your brake shoes can freeze to the drum. You can use a hammer and bar to break them apart. Or, simply wait to set your brakes at night when you park. Wait for your brakes to cool down and back up a few feet before setting them.

3. Complete Daily Pre-Trip and Post-Trip Inspections

While preventative maintenance is crucial to preventing costly downtime, so is completing daily pre-trip and post-trip inspections to ensure the truck is in good working order. Inspections are also mandated by the Department of Transportation (DOT). If you are stopped by DOT, you didn’t do a pre-trip inspection and they catch a violation, you could be fined immediately or have your vehicle rendered “out of service.”

Pre-trip inspections help you catch something potentially problematic before you get on the road. Post-trip inspections help you catch issues at the end of the day so you can be proactive and try to get them fixed before you get back on the road.

Every time you start driving for the day, you will need to check the following during you pre-trip:

- Fluid levels

- Potential leaks

- Tires

- Brakes

- Wipers

- Mirrors

- Horn

- Steering

- Fifth wheel

- Ball joints

- Kingpin

- Lights

- Gauges

Walk around your truck to make sure nothing is visibly out of place as well. Ensure no one messed with your freight during the night.

You also need to be sure that your tires are all moving. If one of them is stuck, you can get miles down the road with it just dragging along before it blows.

When you complete your pre-trip inspection, record it.

You’ll also need to do a post-trip inspection reviewing similar things, like brakes, steering, lights, tires, wipers, mirrors and the horn.

If you are unsure how to do a proper pre- and post-trip inspection, talk to your trucking carrier for guidance or visit this guide to pre-trip inspections.

Lease a Well-Maintained Truck

Focus on finding a good carrier that provides good equipment and prioritizes preventative maintenance. When you do, you’ll be blessed with shop technicians who will anticipate how long you’re on the road and how long until you’ll be in the shop next and they’ll replace fluids and parts in anticipation of this to keep you up and running.

You might have hours of preventative maintenance at once, but it will be well worth it if it prevents you from being down for three days. It’s better to have it done in one visit, rather than several. Ask for a list of services completed and talk through all the repairs to ensure you understand what was fixed.

There is no crystal ball that says when a truck will or will not fail, but technicians do their best.

Our affiliate company, Competitive Equipment Sales (CES) offers newer lease equipment and catastrophic thirty-day “bumper-to-bumper” warranties.

Submit an application to learn more.